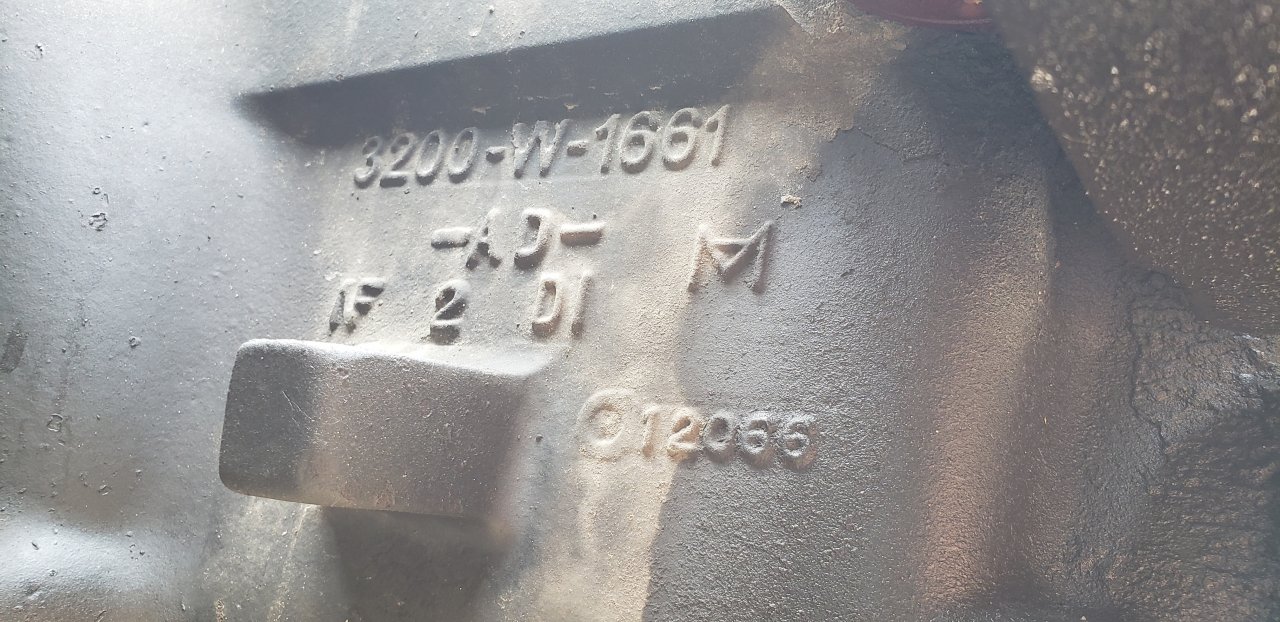

I have Meritor axles. I'll post pics of the data plates from my phone. I'm getting input and output shaft pinion seals and new nuts. Just want to make sure International is getting me the right stuff. For example, one of the nuts they're getting me is a 40x1234, but the parts breakdown shows 40x1233 and 40x1237. Not sure if there's a difference.

Do you know the correct part number for both seals and both nuts? Also what size sockets do I need? I want to get the sockets lined up before I pull this diff. Thanks.

Also, are these axles worth AF? Are they "ole reliable", or are they problem-prone?

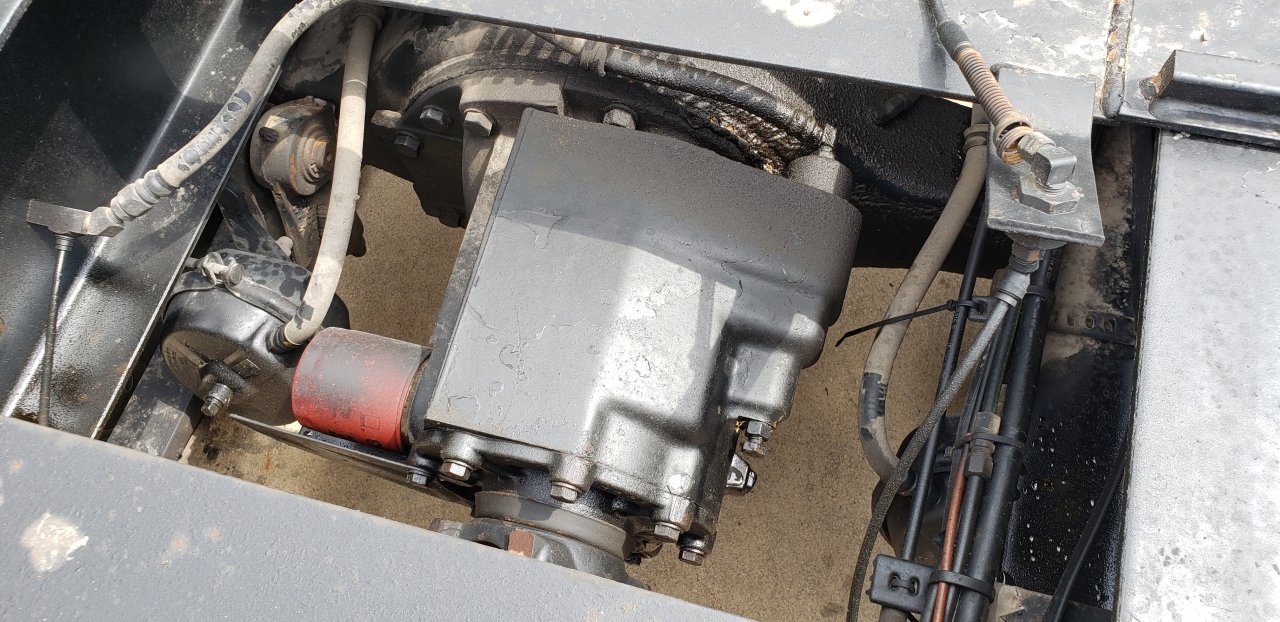

Edit: For clarification, I'm only doing work on the front end. Pulling the diff to reseal it, and need to replace the front pinion seal. Since I have to pull the rear yoke, I'm going to do both seals while I'm in there. Sick of gear oil getting all over my truck and trailer.

Rearend parts

Discussion in 'Heavy Duty Diesel Truck Mechanics Forum' started by God prefers Diesels, May 11, 2021.

Page 1 of 3

-

-

Trucking Jobs in 30 seconds

Every month 400 people find a job with the help of TruckersReport.

-

Couldn't make the tag clearly but ,looks like 40's , on hockey stick .I'm in the process of downing a set and checking them out (3.42), pulled the front stump and replaced oil feeder plate to the bearing . Can't remember the seal #'s off hand but , I keep a log on each component repaired or checked such as bearing #s, seals. You may have to get a mm socket to fit , I think that I tried sae and wasn't it. I do remember that I used Seals ( #'s won't match yours) that didn't require a ware ring so I pulled the ring off, if your ring don't have a deep grove worn in it , you can just replace the seal. Rings are on the yokes and the original will also have a dust ring made with it. I'll try to get a size for the nuts , I reused the old ones , they was locking style.

tommymonza and God prefers Diesels Thank this. -

For the longest time you couldn't pay the loggers around here to take a truck with Eaton diffs. If they weren't Merritor they wouldn't touch the truck with a 10 foot pole.

Take what you will from that statement.tommymonza and God prefers Diesels Thank this. -

There were a few updates on the seals and the nuts over the years.

There are tools you will need to install the seals and the wear sleeves.

Will the shop supplying the parts lend you the tools?God prefers Diesels Thanks this. -

The seal I installed was national # 100494 ( 3.253x4.249x0.635 ) input ,remember I pulled the wear ring . Industry # r945007 seal - input nut 2.20" and output nut 2.150" you can invert this to mm so you'll know what size sockets you'll need . I think I used a 2 3/16 " on rear but had to get a mm to fit the front yoke nut, yours should be the same but , don't hold me to it ,you could have a little different nut. Get on line and look for PB-12112 it's a parts break down for mertior. btw , I hope you seen the post , I wanted to clarify about tire wear you posted earlier, I was thinking off road, on road I keep tires within 3/4" of diameter . Hope you can find this info useful .

John E. and God prefers Diesels Thank this. -

Those differentials are great for over the road service. The new style Merritor seals are really good. If the yoke is badly worn you would need to replace it with a Merritor seal. After market has seals with wear rings available. Do not have to buy a new yoke that way.

While the yoke nuts are lock nuts they are considered a one time use item. If you reuse them apply lots of locktite.

If you are replacing the through shaft seal ( one out the back of the front differential ) it is a good idea to pull that shaft and bearing assy out. It is not a lot more work to inspect those bearings while you are at it.

I am more concerned about if those u joints have grease fittings than if your diffs are worthy.black_dog106, clausland and God prefers Diesels Thank this. -

No, but I want the tools anyway for the future.

I'm doing input and output on the front diff. New seals and new nuts. The U-joints have fittings, and I grease everything regularly. Probably two or three times between oil changes.clausland and BoxCarKidd Thank this. -

Sorry I cannot tell you the nut sizes as I have a shelf full. Believe it was for those units I purchased the 2 3/16 socket mentioned. It is actually metric but that fits. 2 3/4 is common for front yokes. Maybe try to measure it as best you can.

Glad your joints have fittings. Some do not. They are sealed and good for life. When the joints life is over it can take some chambers, air bags and expensive anti lock valves with it. One in particular I know had no play in the joints a week before it blew out. No play because it was seizing with rust.black_dog106, Stray_Dog, clausland and 2 others Thank this. -

I actually went through this with my U joint for life on my 4wd Nissan Pathfinder.

Was getting a vibration in the front end after about an hour that got worse with more speed and than started to pull right.

Immediately checked the sealed front wheel bearings that were a year old. Found one that already had a hard spot in it that was on the right side.

Problem solved I thought.

Threw out all the junk autozone ones even though they were lifetime warranty and bought factory Japanese ones.

Thought I solved the problem. An hour down the road after the repair I had the vibration again.

Checked the ballpoints and tie rods though I knew they were fine.

Checked and pryed on the front driveshaft and it was tight.

This is a Florida car that has been in 4 wheel 2 hours of its whole life.

Checked the new front tires and found one out of round

So off to the tire store and they replaced them under warranty because they had a run of bad ones.

15 minutes down the road and I knew the problem was not solved.

So I got home thinking it must be the front end coming apart.

For chits and giggles I dropped the front driveshaft.

Totally roached even though it was as tight As a brand new healthy Universal .

Greaseless fittings suk.clausland, God prefers Diesels, AModelCat and 1 other person Thank this. -

Are merritors a common rearend on International that you know of?

I have the buildsheet for my 97 9300 but I don’t think it specifies brand or rears.

I’ll have to check.God prefers Diesels Thanks this.

Trucking Jobs in 30 seconds

Every month 400 people find a job with the help of TruckersReport.

Page 1 of 3