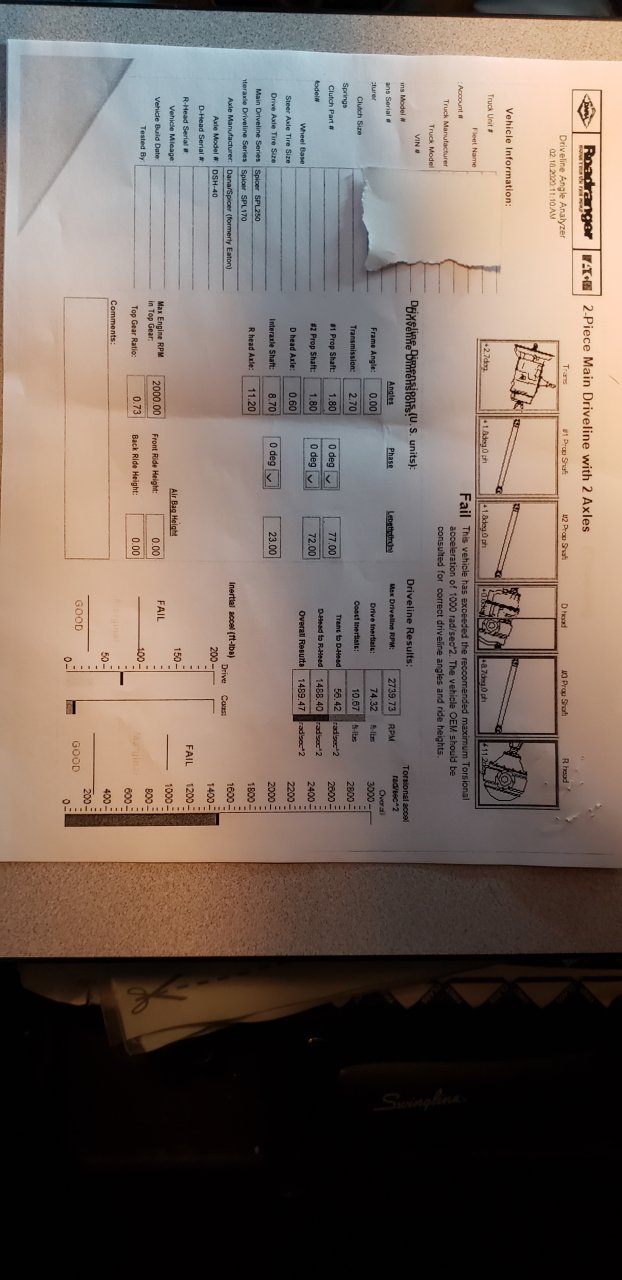

I just had mine done at Peterbilt where I bought my truck as it was a warranty issue. Had lots of vibration. Took them 2 days. According to them it is a step by step process. Had to have clutch adjustment as that is a part of the checking process. Here is the sheet that shows "Fail" when they checked it.

Drive line need 1.5 shim

Do you need to balance drive shaft?

Discussion in 'Heavy Duty Diesel Truck Mechanics Forum' started by Shotgun94, Feb 28, 2020.

Page 3 of 4

-

Rideandrepair, Cabinover101 and Shotgun94 Thank this.

-

Trucking Jobs in 30 seconds

Every month 400 people find a job with the help of TruckersReport.

-

And how old, how many miles to have a fail and it still be under warranty?Rideandrepair and JonJon78 Thank this.

-

How old is the truck? 2020 with 63k miles... I starting noticing vibration around 55k miles or so. I'll have to check my warranty and see how many miles the driveline is covered up to.

I've driven the truck about 5k miles since it was repaired and so far all is good.Rideandrepair, Shotgun94 and Cabinover101 Thank this. -

When I did mine, I had to take front driveshaft in and have a new yoke welded on, I got mad, at them, since not only did they not balance it, they took the weight that was on it off. So a few weeks later, after breaking a bolt off, Had a yoke welded on the rear drive shaft, at a different shop. Same deal, no balance. So I see a new set at Dealer in Ohio, asked about price. They said it was rebuilt by a shop in Detroit, balanced as a set. The shop? The same shop I used the second time. I spent almost $1000 doing it myself, and a lot of running around, waiting a couple days each time. For that reason, it may be best to have a good Shop with a balancer do the work. Unless on a budget, and just need u joint changed. But it’s a heavy pita

JonJon78 Thanks this. -

It is a little running around. Used some ratchet straps to hoist it off, but I’m taking time off. Just waiting on some more tools to get here, then finish it up.

Had a shop balance and put my parts in for 250. He said it wasn’t balanced. He said his machine spun 10,000 rpms. Seemed good and honest guy been doing it awhile, he also marked the shaft so I know how to put it back.

Just been raining here. He said he just used a 9/16 wrench to tighten the bolts when I asked him about torque.JonJon78 Thanks this. -

-

Yes. I just recently put one on my old Pete. It worked. The old solid mount day cabs always seem to have a rattle and vibe on the back wall above the rear mount. You can have everything in the driveline solid and balanced and it will just be there. Not real bad but just annoying. Nature of the beast so to speak. I think its just because there is no way to balance the tranny's. With the ring I figured I’d try it. It is gone. smoooved out the vibe on the sheet metal and silenced the rattle.

They claim it balances everything that runs in that line. So I figure that includes the output shaft on the main trans and the input and output on the aux. trans and input shaft on the inter-axle diff too.Cabinover101 Thanks this. -

How long did the driveshaft have that play/movement in it before you decided to do this project?

That tiger tool seems a lot easier to use from what I've seen online.... What's the deal with it? -

I use there wheel balancers and crank balancer and like them. I have heard some harley guys put them on the primary and it helps smooth things out. I want to add driveshaft balancers.Cabinover101 Thanks this. -

Valley Auto Parts in Warren on Groesbeck. Excellent work and usually the same day service. Rebuilt mine for about $1kRideandrepair Thanks this.

Trucking Jobs in 30 seconds

Every month 400 people find a job with the help of TruckersReport.

Page 3 of 4